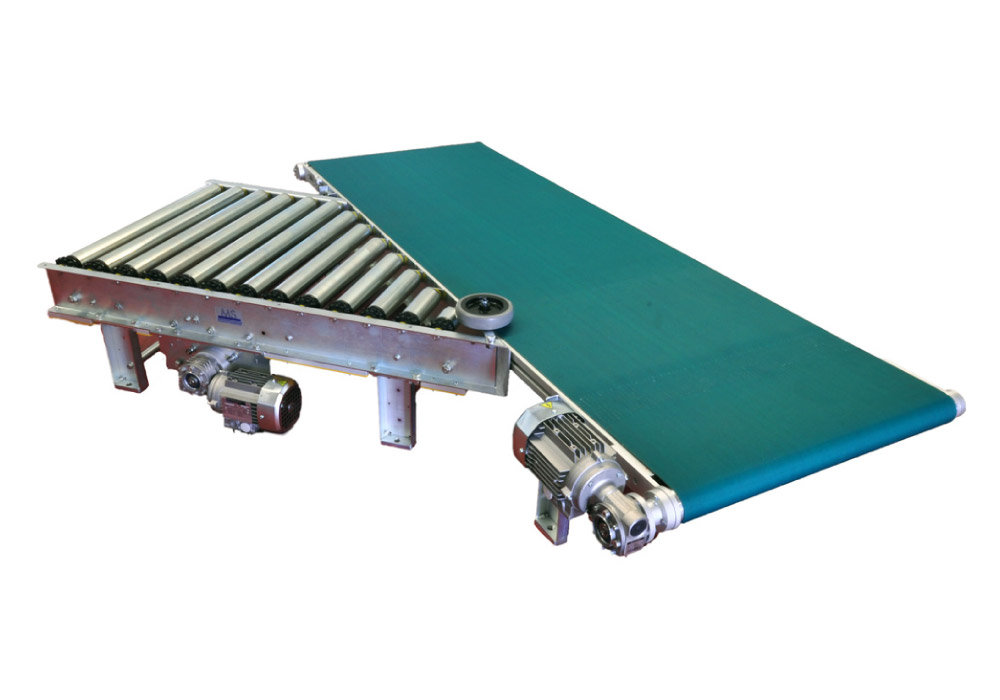

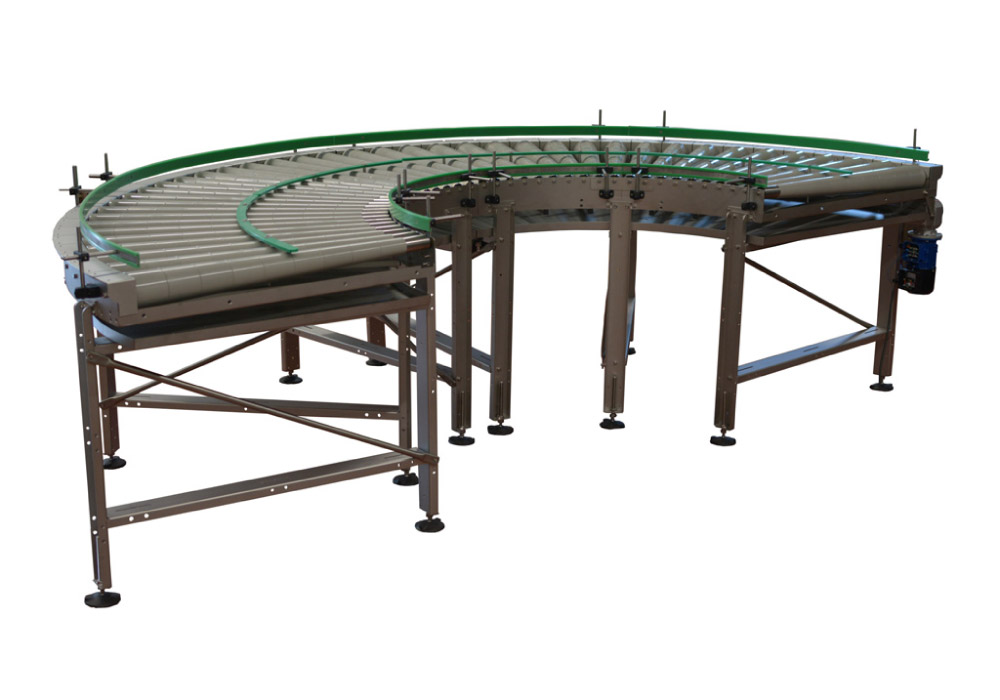

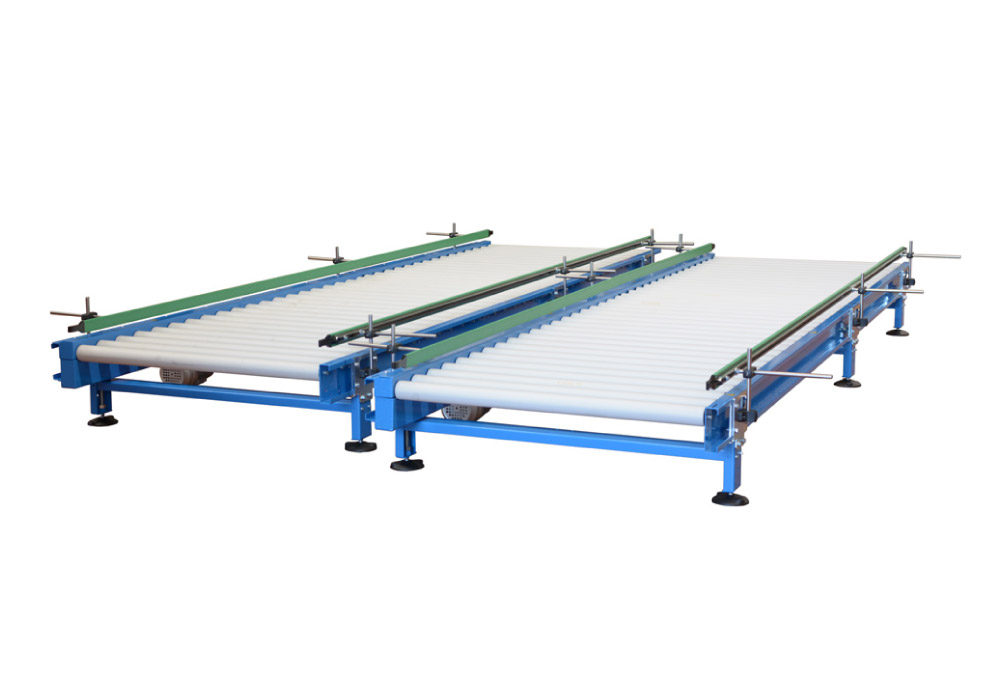

Linear and curved

Motorised roller conveyors

Motorised roller conveyors are designed to guarantee smooth, safe and automised transport of packages of different dimensions and types.

Thanks to their strong and sturdy structure they ensure reliability and resistence over time, optimising logistic and production processes.

Motorised roller conveyors and their characteristics

- Made to measure: motorised roller conveyors can be made according to specific customer requirements

- Utmost safety: they conform to workplace safety regulations and the EC Machinery Directive.

- Robust: the structures are built with galvanised steel or epoxy powder-coated for better protection.

- Adjustable supports: curved roller conveyors are supplied with adjustable supports making them perfectly adaptable to all work environments.

Uses and advantages

- Optimising logistics: they improve work flow, reduce move time and costs.

- Operational efficiency: they are perfect for production lines, automised warehouses and sorting hubs.

- Reliable over time: high quality materials provide better resistence in the long term.

- Totally versatile: dimensions and technical features can be personalised during quotation preparation.

Why choose Mancini Solutions

Our motorised roller conveyors are the best choice for companies wishing to automate internal package handling safely and efficiently. Thanks to attentive and personalisable design, we offer tailor-made solutions for every situation.

Types

- Motorised/Friction roller conveyors with painted steel chain drive

- Motorised/Friction roller conveyors with AISI 304 stainless steel chain drive

- Light-duty flat belt roller conveyor with standard lengths and widths

- Motorised curved roller conveyors with plastic or zinc-coated steel rollers

- Motorised curved roller conveyors with plastic rollers and AISI 304 stainless steel structure

- Motorised 45° roller conveyors for side line entry

- Heavy-duty motorised roller conveyors for pallet handling

Characteristics

- Weight-bearing structure in AISI 304 powder-coated or stainless steel

- Zinc-, rubber-coated or AISI 304 stainless steel rollers

- Standard widths 400 / 500 / 600 / 700 / 800 mm

- Standard lengths 500 / 1000 / 1500 / 2000 / 2500 / 3000 mm… up to 6000 mm

- Standard roller pitch 69 / 101 / 203 mm

- Chain-drive v-belts or flat transmission belt

- Support with self levelling and plugable feet

- Motorised/Friction roller conveyors in AISI 304 stainless steel

- Motorised 45° or 90° curves and widths of 400 / 500 / 600 / 700 / 800 / 900 / 1000 mm

Settori di impiego

- Food and Beverage

- Pharmaceuticals

- Manufacturing industries

- Restaurants

- Packaging

- Automations

- Robotics

- Automotive

Accessories

- Control system with overload relay (gear/stop and emergency)

- Speed control inverter (gear/stop/emergency and e potentiometer)

- PLC-based integrated electric system for management of ready-to-use installations

- Adjustable or fixed guides

- Mechanical or pneumatic stop bars

- Pneumatic or electric actuators

- 90° orthogonal diverter with belts

- Dual motor

- Wheels with brakes

- Accessory mounting plates

- Rubber coated and specific rollers according to requirements

- Pneumatic actuators

- Box centering device

Options and customizations