Pallet movement conveyors

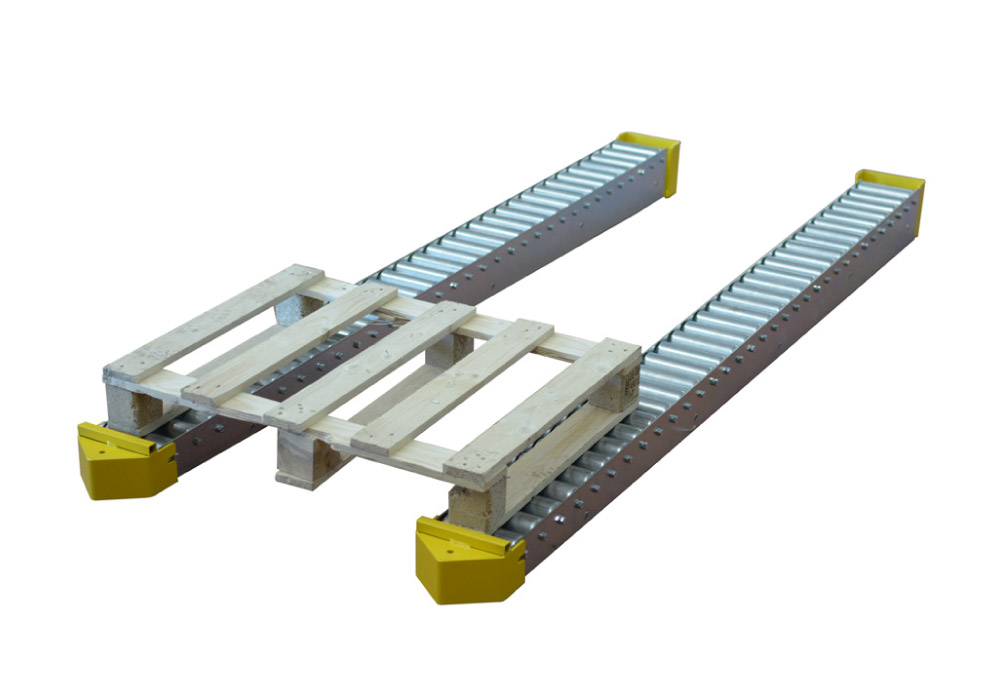

PALLET MOVEMENT CONVEYORS

Movement

Pallet movement inside the warehouse and production areas also represents a fundamental element of time optimisation, so storage and transport must be planned with careful attention. Whether you seek a complex storage system, to increase productivity, or simply need a transport line for pallets, barrels, chests or heavy and large loads, Mancini Solutions has the solution that will allow you to successfully reach your objectives.

Types

- Motorised conveyors of any dimension and load capacity

- Gravity roller conveyors of any dimension and load capacity

- Chain conveyors (catenary)

- Gravity rotating roller conveyors

- Motorised rotating roller conveyors

- Chain or belt orthogonal diverters

- Hydraulic pallet lifts

- Motorised and manual shuttles

- Heavy-duty ball bearing conveyors

Characteristics

- Weight-bearing structure in AISI 304 powder-coated or stainless steel

- Zinc-, rubber-coated or AISI 304 stainless steel rollers

- Standard widths 900 / 1000 / 1100 / 1200 / 1300 mm… Up to 2000 mm

- Standard lengths 500 / 1.000 / 1.500 / 2.000 / 2.500 / 3.000 mm… Up to 6000 mm

- Standard roller pitch 101 mm

- Ring-chain transmission

- Supports with self levelling and plugable feet

- Motorised/Friction roller conveyors in AISI 304 stainless steel

- Motorised 45° or 90° curves and width of 1000 mm

Areas of use

- Food and Beverage

- Pharmaceuticals

- Manufacturing industries

- Restaurants

- Packaging

- Automations

- Robotics

- Automotive

Accessories

- Control system with overload relay (gear/stop and emergency)

- Speed control inverter (gear/stop/emergency and e potentiometer)

- PLC-based integrated electrical system for management of ready-to-use installations

- Adjustable or fixed guides

- Mechanical or pneumatic stop bars

- Pneumatic or electric actuators

- 90° orthogonal diverter with belts

- Dual motorisation

- Wheels with brakes

- Accessory mounting plates

- Rubber coated and specific rollers according to requirements

Options and customizations